AGRITECHNICA 2023 - Exhibits

Pest control with the LichtFalle

Using lasers for pest control can be an element of sustainable crop protection - and an important step towards digitalizing food production. The LichtFalle is an autonomous system that uses AI-powered laser technology to startle, attract, map, and selectively control insect pests.

The system can maneuver autonomously through greenhouses, startle insects from the plant stand, attract them via LED light surface, and then render them harmless with the laser (exemplified in the demonstrator).

The difference to the classic yellow panel is the AI-supported, automated differentiation of insect species based on image data. An integrated camera module looks at the LED surface and automatically recognizes whether the insect is a pest or a beneficial insect. As a result, all harmless insects, and especially beneficial insects, can leave the attraction panel unmolested without laser treatment.

Motivation

• reduction of the use of chemical pesticides

• enable more efficient and resource-conserving food production

• develop a digital decision support system for pesticide use and other control strategies through live monitoring

Applications

• in greenhouses

• in open land

Advantages

• only selected insect pests are treated, leaving beneficial insects unharmed

• live monitoring of different insects in the plant population

• targeted attraction of specific insects

• highly effective attraction due to LED technology

• targeted use of the LichtFalle in areas of high pest occurrence

Additive Manufacturing in agriculture

Agriculture is an industry that can benefit greatly from additive manufacturing. For example, when it comes to the repair and wear protection of highly stressed parts: Powder or wire welding can be used to add wear-resistant layers to surfaces, and damaged parts can be rebuilt and repaired. Additive manufacturing also makes it possible to produce components tailored to the application and user - the seed skid is an interesting example. New design options and weight-optimized components can make agricultural machinery lighter and more efficient in the future.

Last but not least, additively manufactured spare parts for agricultural machinery can be produced promptly in the 3D printer - a way to become less dependent on supply chains and manufacturers and more flexible in responding to demand.

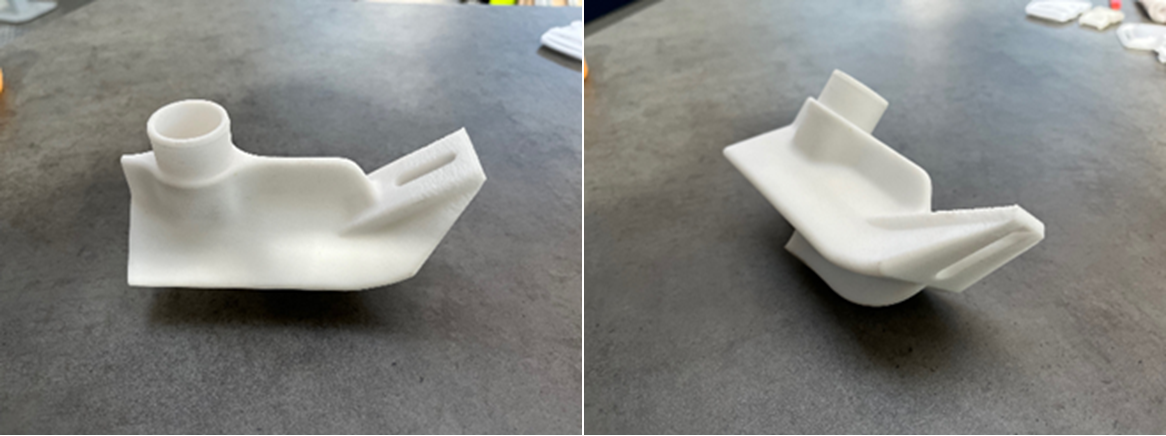

Exhibit seed skid

The technology available on the market for seed skids is either very expensive or does not achieve the desired effect. This is particularly costly during dry periods when a large proportion of seeds fail to germinate. The seed skid, which was developed in a 'Praxis-Check 3D-Druck' with a farmer, fills this gap. The new seed skid opens up the soil, creating a uniformly deep and wide furrow into which the seed is deposited directly via a channel in the component. Older seed drills can be retrofitted with additively manufactured skids at a low cost.

Applications

• In tillage when sowing seed crop

Advantages

• Component can be quickly retrofitted, wear-resistant, and cost-effective.

3D printing process

• SLS process

• Material: PA12

Exhibit „Gubberschar“ (cultivator)

Cultivators are used as tools in soil cultivation. They are used to mix the soil, e.g. to incorporate crop residues. A refinement of steel with precious metal applied by 3D printing ensures a hardened cutting edge, less wear, and a longer service life.

Applications

• In tillage

Advantages

• Refinement ensures less wear

• Longer service life and thus cost savings

3D printing process

• Laser deposition welding

• Material: stainless steel 316L

Exhibit joystick

In agriculture, there are several different control units on tractors or harvesting vehicles. A variable arrangement of buttons and joysticks enables more ergonomic working. This is because individual user needs become important during 10- to 15-hour operations. 3D printing can be used to make adjustments quickly and easily, and the interior can be expanded on an ongoing basis.

Applications

• Individual arrangement of control buttons and ergonomically adapted joystick for efficient work

Advantages

• Individual configuration of control buttons and geometric adjustments

• Fast adaptation of user needs

3D printing process

• Process: Stereolithography

• Material: Resin

Exhibit sealing collar, gaskets, belts

Production of individual seals in the form of sealing collars or sealing tapes. Individual belts for drives or rubber coatings for e.g. transport rollers are also possible with different degrees of hardness. 3D printing with different materials in granular form enables efficient production without increased material waste.

Applications

• Dampers, stoppers, drive belts, rubber linings of rollers and wheels. Sealing of lids and closures

Advantages

• Individual products, customizable, produced quickly.

3D printing process

• FFF process with filament or granulate

• Material: TPU (Shore hardness 40 – 90)

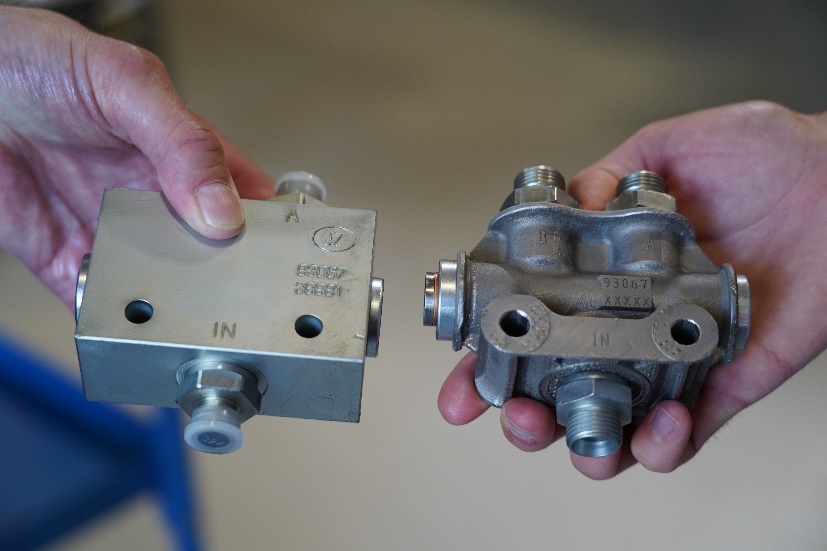

Component hydraulic valve

Hydraulic valves are used in industrial applications such as agricultural machinery, among others. Benefits of hydraulic valves include precise regulation of fluid flow and pressure, improved system efficiency, increased system performance, and protection of the hydraulic system from overload and damage. Prototypes of such valves can be 3D printed and iteratively adapted quickly and without long set-up times. This means that existing equipment for machining can be kept free and used for series production.

Applications

• Prototyping of hydraulic controls e.g. in agricultural machinery

Advantages

• Material savings (additive manufacturing instead of milling)

• Fast replacement of a defective hydraulic valve through 3D printing

• Independence from spare parts manufacturer

3D printing process

• Process: LPBF

• Material: Stainless steel

Further information: https://niedersachsen-additiv.de/praxis-check-ak-regeltechnik/

Weed treatment with the laser

For more sustainable agriculture, the LZH is researching light-based weed control with lasers. Our weed treatment demonstrator shows how laser technology can be used to precisely and selectively kill unwanted plants: The laser beam is used to destroy sensitive parts of the plant, such as the apical meristem or the base of the stem. The lasers used have a beam diameter of a few millimeters and work in a non-contact manner, so the technology can also be used to treat weeds close to crops without harming them.

Artificial intelligence (AI) is used to control the laser treatment. Image recognition is used to distinguish between the crop and the weeds and to determine the target points for the laser.

With this method it is possible to treat individual plants in a very targeted way: Based on different parameters, some plants could be left in place and others irradiated. Moreover, the treatment does not necessarily have to be lethal. It may simply damage the plant so that it needs time to recover (growth retardation). This leads to less competition between crops and greater biodiversity.

Title

Demonstrator laser weed treatment

Motivation

• Development of a more ecologically sustainable alternative to herbicide use in agriculture

• Contribution to the prevention of herbicide resistance in weed control

• Development of a mechanical alternative to manual weed control in crop rows

Applications

• Weed control at close range, even on very young crops

• Selective weed control

Technical specifications

• 100 W laser power

• 1940 nm

• 5,5 mm beam diameter (collimated)

Advantages

• automated process: no labor is required for manual weed control.

• thermal process, therefore no development of resistance

• enables crop growth benefits while maintaining biodiversity

• allows selective treatment of individual plants

See also

• WeLASER: Technical alternative in weed management

• Fighting weeds in sugarbeet cultivation intelligently and precisely with the laser

• Alternative: Laser – Neue Strategie im Umgang mit resistenten Unkräutern (LURUU)