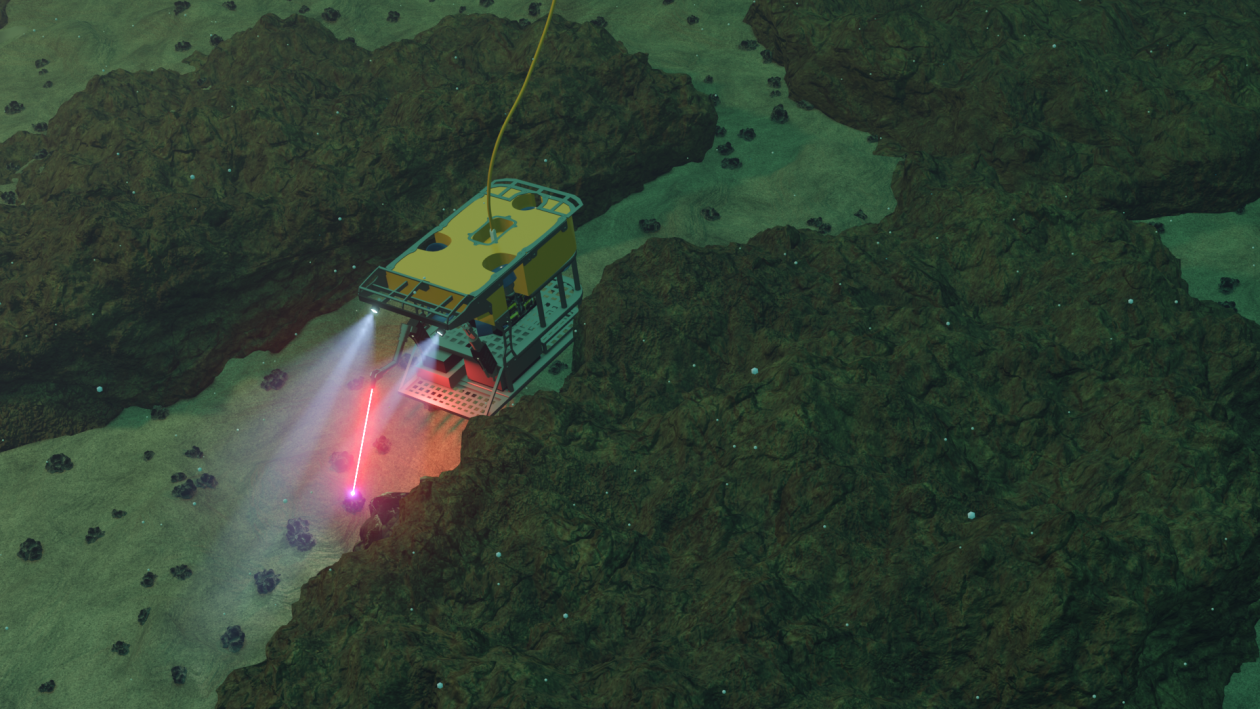

With laser-induced breakdown spectroscopy (LIBS), the LZH has developed a method using double-pulse lasers an environmentally friendly method for analyzing valuable metals such as copper and zinc at 6,000 meters below sea level. These materials are needed to produce components for e-mobility, including electric cars, and for wind energy. The method, which was researched as part of a DFG project, makes it possible to determine materials in real time. To test the method, the scientists from the LZH and the Leibniz Institute for Plasma Science and Technology (INP) in Greifswald set up a test rig. For the first time, they are simulating the conditions on the seabed in a pressure chamber at up to 600 bar. The LIBS system is intended to replace the time-consuming process of taking samples from the seabed, which until now has involved diving robots, often ROVs (remotely operated vehicles), taking samples with gripper arms, which are then examined on board a research vessel or on land.

The double-pulse technique of the new method uses two laser pulses: the first pulse creates a gas-vapor environment (air bubble) in the water on the surface of the material, a so-called cavity. The second pulse vaporizes material from the surface of the sample inside this cavity and creates a plasma containing the elements for spectroscopic analysis. One challenge here is the high pressure under water, which makes it difficult to generate meaningful spectra with a suitable intensity for precise analysis.

Optimized for deep-sea use

The focus of the current research is the analysis of materials at a pressure of up to 600 bar, as prevails at depths of 6,000 meters below the water surface, and the use of laser pulses with energies of up to 150 millijoules. By adjusting the laser parameters, the team was able to optimize the measurements for the high deep-sea pressure. Short delays of 0.5 microseconds between the laser pulses and the precise adjustment of the measurement start times for the spectrometer are crucial for the quality of the data obtained.

The results of the project are summarized in the informative video. It provides insights into deep-sea research and illustrates the new knowledge that researchers can gain about the seabed using modern laser technology.

The research has been published in the journal "Spectrochimica Acta Part B: Atomic Spectroscopy" (DOI: 10.1016/j.sab.2024.106877). The project was funded by the German Research Foundation (DFG) under the project number 454848899.

Laser Zentrum Hannover e.V. (LZH)

As an independent, non-profit research institute, the Laser Zentrum Hannover e.V. (LZH) stands for innovative research, development, and consulting. Supported by the Lower Saxony Ministry of Economics, Transport, Building and Digitalization, the LZH is dedicated to selflessly promoting applied research in the field of photonics and laser technology. Founded in 1986, almost 200 employees are now working at the LZH.

The LZH offers solutions to current and future challenges with its smart photonics. Along the process chain, natural scientists and engineers work interdisciplinary together: from component development for specific laser systems or for quantum technologies to process developments for a wide variety of laser applications, for example for medical and agricultural technology or lightweight construction in the automotive sector. 18 successful spin-offs have emerged from the LZH to date. Thus, the LZH creates a strong transfer between fundamental science, application-oriented research, and industry - and uses light for innovation.