The high-tech incubator SMINT@Hannover is funded by the state of Lower Saxony and is designed to help talented people from universities, higher education institutions, and research institutes turn their ideas into business models - with funding, but also with workshops, coaching, and access to laboratories and technical infrastructure. The goal is to bring research findings to market as quickly as possible in the form of high-tech developments.

3D printing makes it possible: glove with cooling channels for chemotherapy

In addition to scientific expertise, the LZH provides a professional technical infrastructure. This includes access to laser systems as well as various 3D printing systems for Additive Manufacturing. Two technology ideas come from the LZH that are now being implemented as part of the incubator following the Venture Lab approach of Nexster, the Entrepreneurship Center of the Hannover University of Applied Sciences and Arts.

The founding team PNProtect is working on a cooling glove for cancer patients. During chemotherapy, it is common for the strong medication administered to damage the nerve endings in the fingers and feet, causing patients to develop polyneuropathy (PNP). To avoid this, the patients wear mittens with cold packs. These release the cold uncontrollably and prevent the patients from using their hands - very uncomfortable during the treatment, which often lasts for hours. An additively manufactured silicone glove with integrated cooling channels is intended to remedy this situation: It enables uniform, sensor-monitored cooling of the entire hand without restricting hand and finger motor function.

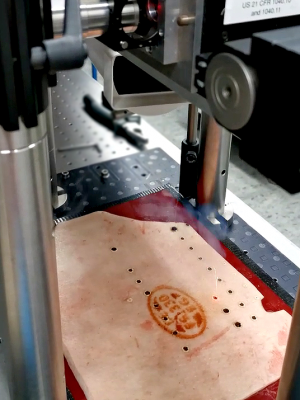

Laser markings for more transparency in meat production

A novel laser marking process for animals in industrial meat processing plants, which has already been patented by the institute, is now also being implemented. The process aims to uniquely mark the animals with a laser label and make them traceable using an image recognition process. This could, for the first time, ensure the complete traceability of individual animals within a slaughterhouse - in line with the farm-to-fork approach for greater safety and sustainability in food production. The founding team TiWoLa 3000 now wants to put the process into practice.

The LZH closely accompanies the implementation of the ideas by the founding teams with advice and infrastructure. However, the institute also supports all other founders in the SMINT incubator and accompanies the technology ideas on their way to independence.

About the SMINT@Hannover

The high-tech incubator SMINT@Hannover for information technology startups was initiated under the leadership of Leibniz University Hannover (LUH) by the LZH, Hannover University of Applied Sciences and Arts, VentureVilla, and hannoverimpuls. It is one of eight high-tech incubators in Lower Saxony, which the Lower Saxony Ministry of Economics, Transport, Building and Digitalization is funding with a total of around 35 million euros. SMINT@Hannover focuses on startup activities in the fields of Additive Manufacturing, biomedical technology, mobility, and production technology. Eleven startups and nine founding teams are currently funded in the incubator. More information is available here.

Partner

Laser Zentrum Hannover e.V. (LZH)

As an independent, non-profit research institute, the Laser Zentrum Hannover e.V. (LZH) stands for innovative research, development, and consulting. Supported by the Lower Saxony Ministry of Economics, Transport, Construction and Digitalization, the LZH is dedicated to selflessly promoting applied research in the field of photonics and laser technology. Founded in 1986, almost 200 employees are now working at the LZH.

The LZH offers solutions to current and future challenges with its smart photonics. Along the process chain, natural scientists and engineers work interdisciplinary together: from component development for specific laser systems or for quantum technologies to process developments for a wide variety of laser applications, for example for medical and agricultural technology or lightweight construction in the automotive sector. 18 successful spin-offs have emerged from the LZH to date. Thus, the LZH creates a strong transfer between fundamental science, application-oriented research, and industry - and uses light for innovation.