Building on initial successful laser fusion experiments, the PriFUSIO project aims to develop powerful, reliable, and cost-effective laser sources and optics as well as automated solutions for fuel supply and the efficient use of the waste heat generated. In this way, the partners want to explore the possibilities for the commercial use of laser-ignited inertial confinement fusion.

From the greater Hanover area, the medium-sized company LASEROPTIK GmbH, Garbsen, and the LZH are contributing their expertise in the field of optical coatings to the project.

High-performance optics for high-power lasers

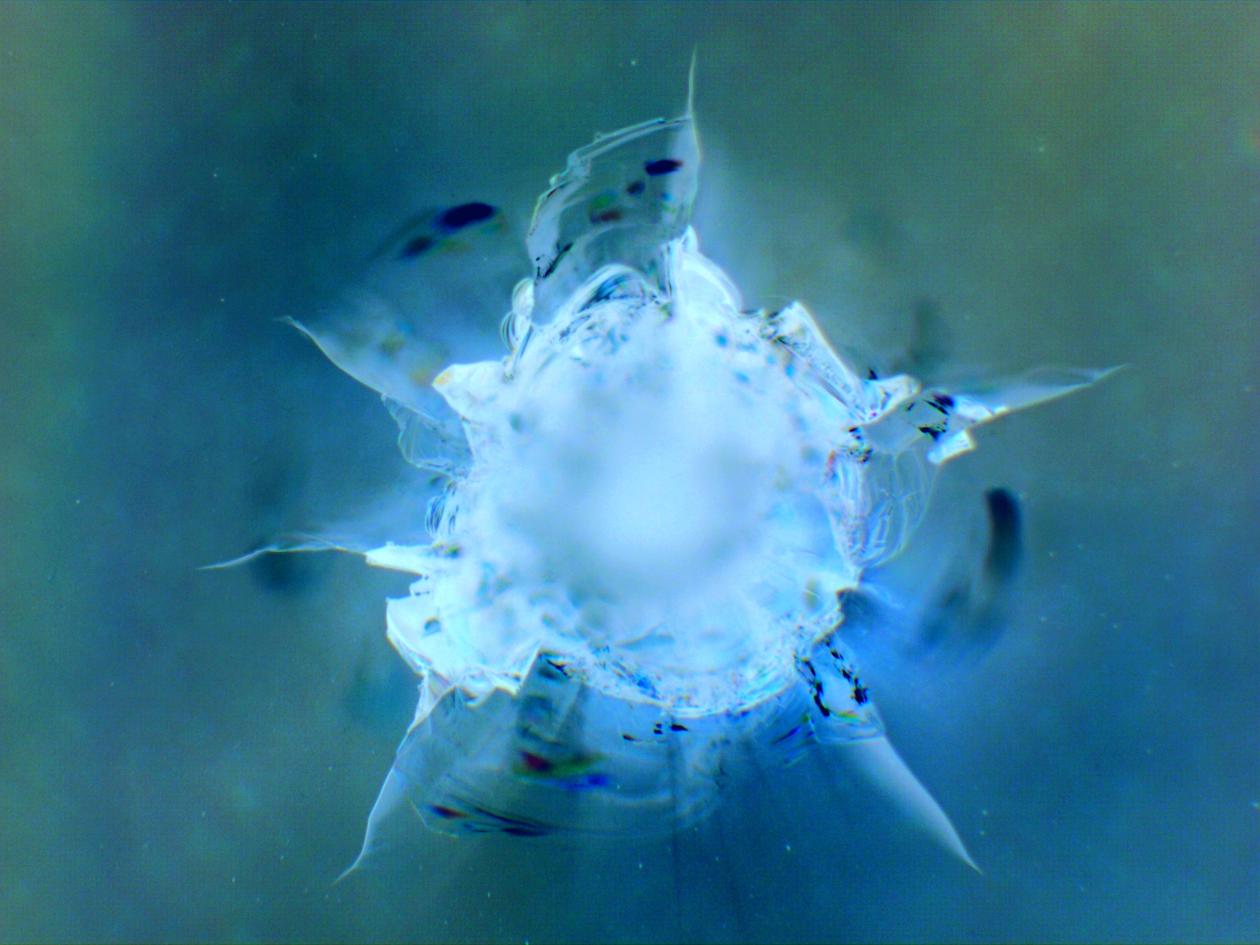

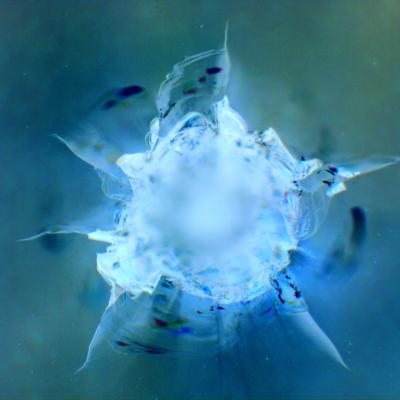

Within PriFUSIO, the LZH is researching new measurement methods for characterizing the laser induced damage threshold (LIDT). This involves exposing optics to increasing laser power until they are destroyed.

"The optics are the weakest link in the chain of such powerful lasers," explains Dr. Dietmar Kracht, CEO of the LZH. "We are extremely pleased to contribute our expertise in the field of damage threshold measurements to the project in order to qualify optics for even higher powers."

Better understanding of destruction behavior

On the one hand, the researchers at the LZH want to make time-resolved measurements of the LIDT possible with pump-probe experiments. To do this, they send a high-energy laser pulse as well as a second measuring laser pulse through the optics. With this, they expect a better understanding of the effects that lead to the destruction of the optics.

The researchers are also working on measuring particularly large optics of up to 30 cm in diameter. These are usually around one inch, i.e. approx. 2.5 cm in size. To this end, they are developing automated measurement routines with high laser power and very short pulses and are using image recognition based on artificial intelligence. The planned measurement setup will be mobile so that it can also be used at the other partners. The LZH also wants to enable benchmarking in the project, i.e. make the partners' work comparable.

Highly reflective optics with homogeneous coatings

LASEROPTIK GmbH will develop new types of coatings for highly reflective optics to further increase their laser damage threshold and service life. This includes the development and optimization of innovative coating technology for larger optics. The Garbsen-based company has already made a name for itself internationally in other projects with its ion beam sputtering technology.

"It is a special honor to be able to work on this outstanding project. In view of the dedicated project goals, this is a very serious commitment that we want to take on," comments CEO Dr. Wolfgang Ebert on his company's involvement.

In the PriFUSIO project, the LZH will work together with Schott AG, Heraeus Group, TRUMPF Laser AG, the start-ups Focused Energy GmbH and Marvel Fusion GmbH, as well as the medium-sized companies LAYERTEC GmbH and LASEROPTIK GmbH, and the Fraunhofer Institute for Applied Optics and Precision Engineering IOF, under the direction of the Fraunhofer Institute for Laser Technology ILT, Aachen.

The BMBF-funded project is part of the "Fusion 2040 - Research on the way to the fusion power plant" funding program. The aim is for Germany to be one of the first countries in the world to develop and build a fusion power plant.

Further information on the project, laser fusion research and the roles of the other partners can be found in the Fraunhofer ILT press release: https://www.ilt.fraunhofer.de/en/press/press-releases/2024/4-16-collaborative-project-prifusio-fusionresearch.html

Laser Zentrum Hannover e.V. (LZH)

As an independent, non-profit research institute, the Laser Zentrum Hannover e.V. (LZH) stands for innovative research, development, and consulting. Supported by the Lower Saxony Ministry of Economics, Transport, Building and Digitalization, the LZH is dedicated to selflessly promoting applied research in the field of photonics and laser technology. Founded in 1986, almost 200 employees are now working at the LZH.

The LZH offers solutions to current and future challenges with its smart photonics. Along the process chain, natural scientists and engineers work interdisciplinary together: from component development for specific laser systems or for quantum technologies to process developments for a wide variety of laser applications, for example for medical and agricultural technology or lightweight construction in the automotive sector. 18 successful spin-offs have emerged from the LZH to date. Thus, the LZH creates a strong transfer between fundamental science, application-oriented research, and industry - and uses light for innovation.