Welding steel components more efficiently with thick wire

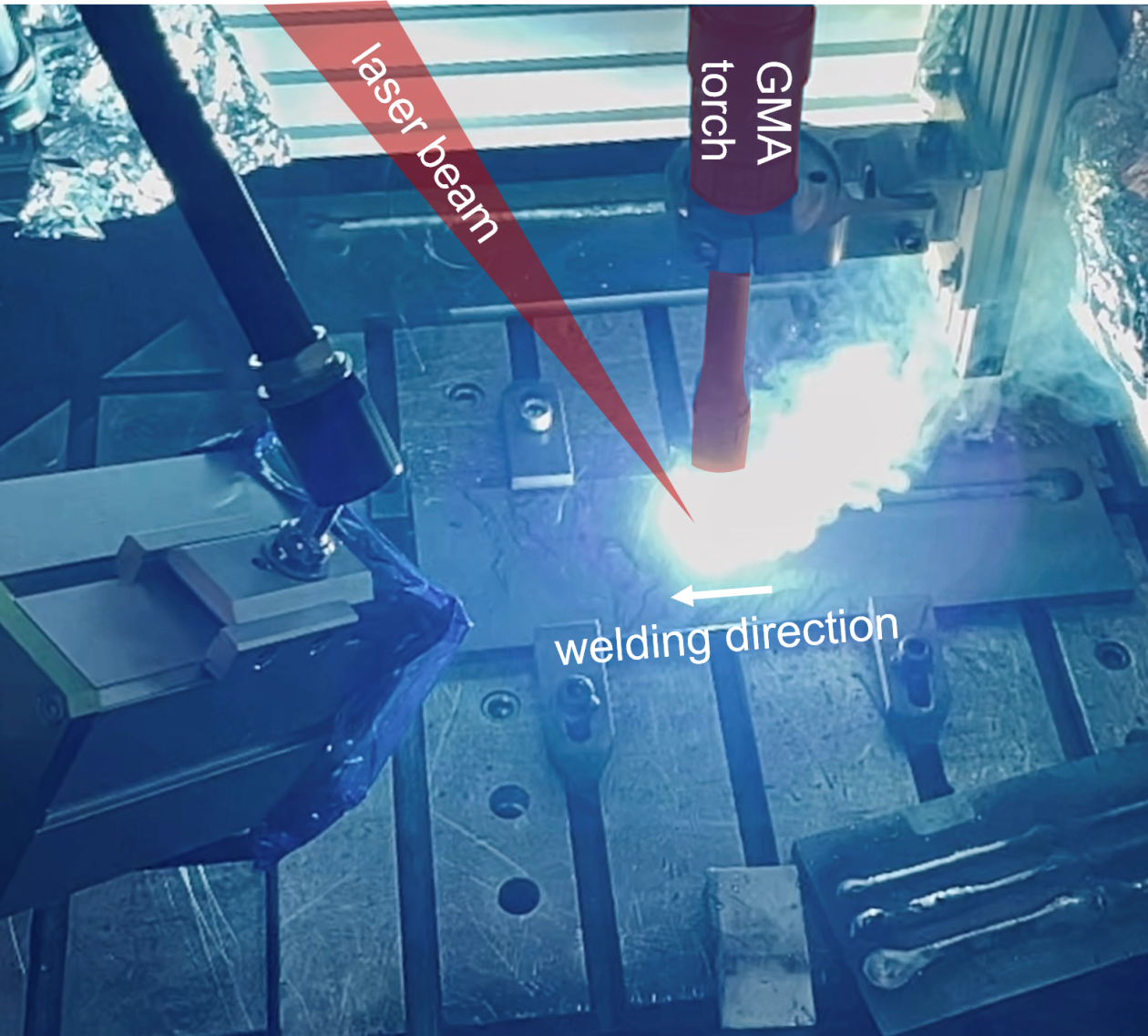

When welding thick sheets, large seam gaps must be bridged. Researchers of the "ÖkoHybrid" project want to enable to close the gaps with fewer layers, by feeding in relatively thick wire with a diameter of 3 mm. This should make the joining process significantly faster and more resource efficient. They use an additionallaser beam to accelerate and stabilize the process.

Stable hybrid welding process thanks to high-performance welding power source

As part of the "ÖkoHybrid" project, the LZH scientists are investigating welding processes on fine-grain structural steels with sheet thicknesses of up to 20 mm. To this end, they will develop and build a new type of hybrid processing head. Thes want to combine a commercially available laser beam source with an output of 3 kW and a welding power source with an output of up to 40 kW. The welding power source is being developed by project partner ELMA-Tech GmbH. The project partner FÖRSTER welding systems GmbH will realize a complete system for the hybrid welding process. The Westsächsische Hochschule Zwickau will carry out fundamental investigations into the MSG welding process, and also test and characterize the welded joints.

Hybrid laser arc welding combines the advantages of gas metal arc welding (GMAW) of thick wire with those of laser beam welding in a common process zone. The combined processes achieve a high deposition rate and a high welding speed. The use of 3 mm thick wires allows a large amount of material to be inserted, significantly reducing the number of layers to be welded and thus increasing efficiency. The additional laser beam increases the process stability.

Steel components in the heavy sheet sector: great demand for fast processes

Fine-grained structural steels are used in ship, vehicle and pipeline construction, for example. They have a higher strength than conventional structural steels, which is why lower material thicknesses can be used. This makes it possible to use less material and consequently reduce the weight of the components. However, the material has high demands on the welding process: for example, cooling too slowly during the welding process leads to insufficient strength and toughness. If it cools too quickly on the other hand, cracks and seams with high hardness can form. The scientists therefore want to increase the welding speed and deposition rate while maintaining the required cooling times.

About ÖkoHybrid

The sub-project "Process development for laser beam MIG hybrid welding with larger wire diameters" is funded by the Federal Ministry for Economic Affairs and Climate Action (grant no. KK5111716KT3) as part of the project "Economical high-performance welding of fine-grain structural steels using laser MSG hybrid welding of larger wire diameters (ÖkoHybrid)" within the framework of the "Central Innovation Programme for SMEs (ZIM)".

Laser Zentrum Hannover e.V. (LZH)

As an independent, non-profit research institute, the Laser Zentrum Hannover e.V. (LZH) stands for innovative research, development, and consulting. Supported by the Lower Saxony Ministry of Economics, Transport, Building and Digitalization, the LZH is dedicated to selflessly promoting applied research in the field of photonics and laser technology. Founded in 1986, almost 200 employees are now working at the LZH.

The LZH offers solutions to current and future challenges with its smart photonics. Along the process chain, natural scientists and engineers work interdisciplinary together: from component development for specific laser systems or for quantum technologies to process developments for a wide variety of laser applications, for example for medical and agricultural technology or lightweight construction in the automotive sector. 18 successful spin-offs have emerged from the LZH to date. Thus, the LZH creates a strong transfer between fundamental science, application-oriented research, and industry - and uses light for innovation.