LASER - World of PHOTONICS 2023: Optical Components

Contact

Phone: +49 511 2788-419

Email: messe@lzh.de

Smart Optical Coatings

Motivation

• Production of high-end optical components

• Functionalization of surfaces with optical coatings

• Flexible optical & mechanical properties

• Protection layers

Function/Properties/ Characteristics

• Various processes for all sample types'

• Ion Beam sputtering for high-precision coatings

• Atomic layer deposition for free-form components

• Thermal processes for expanded material range

Applications

• High-power applications

• Precision metrology

• Integrated optical systems

rALD Coatings

Motivation

• Rising form complexity of optics

• CNC milling, polishing

• 3D printed, injection molding, casting

• Need of conformal coatings

• Sensitive materials

Function/Properties/ Characteristics

• High conformal, low temperature coatings

• Large areas up to 200 mm diameter

• Low spectral absorption

Applications

• Planar and non-planar optics

• Aspheres, Fresnel lenses, prisms

• Gratings

• Capsuling

• e.g. laser crystals

Parameters

• ~0.14 nm/sec growth rate

• 150°C deposition temperature

Processed material

• 200 nm Ta2O5

• 8’’ silicon wafer

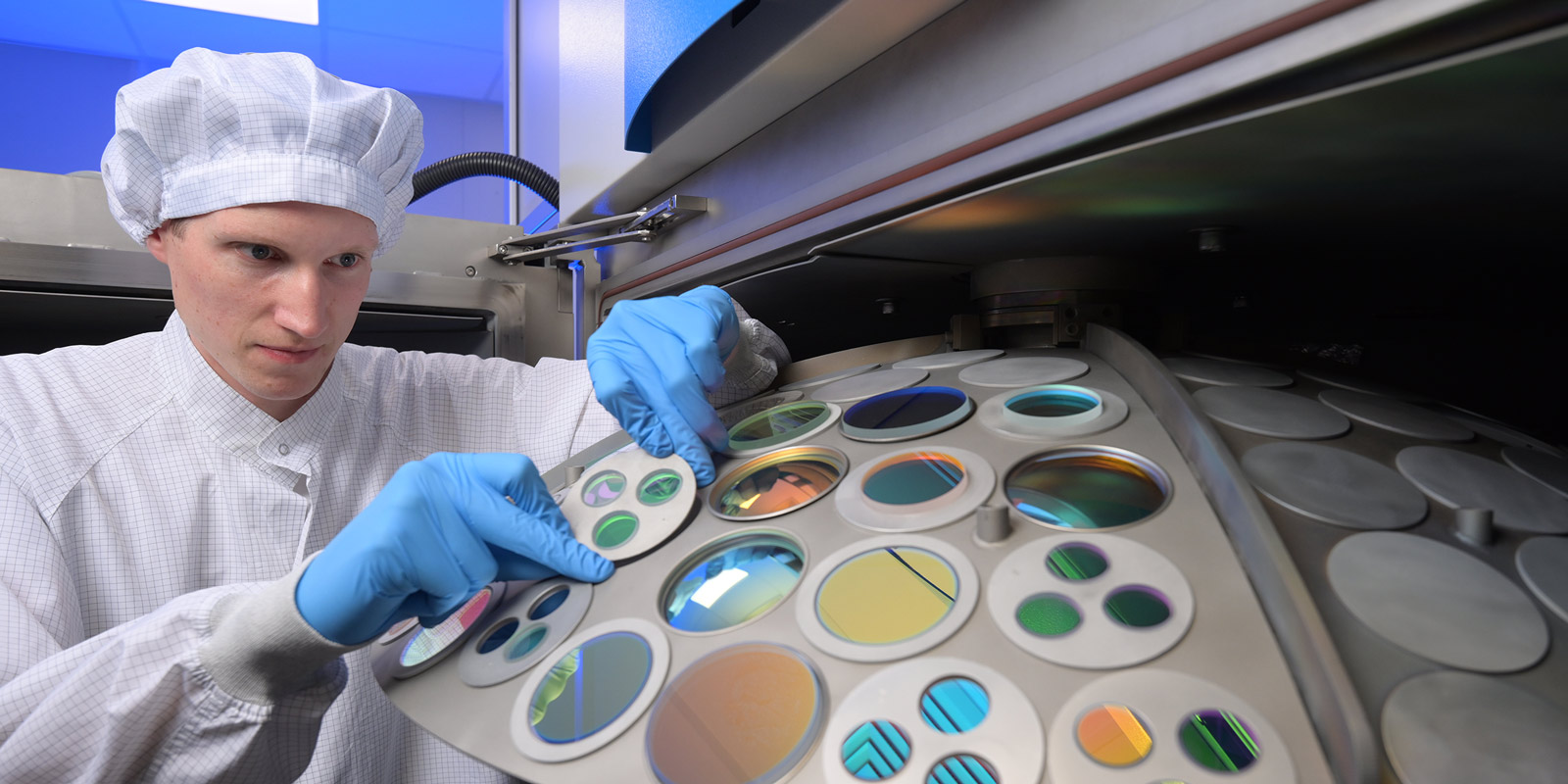

Sample loading

• Direct or via load lock

Outstanding growth rate

• Up to 1000 nm/h

• Temperature range 25-200°C

Batch size

• 7 pieces 200 mm

• 13 pieces 100 mm

• 384 pieces 25 mm

IBS Coatings

• Highest coating precision, nearly perfect thin film structure

• „Cold“ deposition process (< 80 °C)

• Sputtering of the target material, substrates are deposited with sputtered particles

• Oxides, (fluorides), metals

• Applications: DUV, UV / VIS-IR, high fs-LIDT

Miniaturized optical thin film filters

• High-precision IBS coating on wafer with sacrificial substrate

• Laser cutting into single filter elements

• Transfer to tape via dissolving sacrificial substrate

• Filter edge length 25 µm up to 1 mm with rectangular or freeform shape

• Miniaturization allows for high integration density in hybrid photonic systems or telecom fiber applications

• Substrate-free technique enables low loss integration between waveguides or fibers

High Resolution Optical Broadband Monitoring

Motivation

• Precise in situ coating thickness monitoring for production of optical thin-film filters

Function

• Direct broadband measurement of moving substrates on rotating substrate holder in UV to NIR wavelength range

Applications

• Precise deposition control

• Online characterization of coatings

• Automated process control

• Rapid manufacturing of complex optical designs

• Faster development of new coating processes

• Quality control and documentation of production processes

• Increased process yield using advanced simulation, re-optimization and error handling tools

• Modular system, flexible configuration according to customer specification in wavelength range and resolution

Technical data

| BBM | HR BBM | |

| Wavelength range | 240 - 1000 nm optional IR: 240 - 1700 nm |

|

| Spectral resolution | 1 - 1.5 nm IR: 1 - 5 nm |

0.1 - 0.2 nm IR: 0.1 - 3 nm |

| Measurement time | 10 µs - 30 ms | |

| Wavelength accuracy | < 0.5 nm | |

| Reproductibility of 100%-measurement | better ±0.04% | |

| Noise of 100%-measurement | < 1% RMS | |

Performance and Options

• Software algorithms for data acquisition, thickness determination and process control

• BBM simulation module, including a virtual deposition unit: advanced design stability analysis

• Re-optimization module: online error analysis and automated design refinement for increased yield

• Modular system: options for uniformity measurements on multiple radii, combined transmittance and reflectance measurements, spectral resolution below 1 nm (High Resolution / HR BBM)

• In addition to the standard configuration, customized adaptions, e.g. for spectral range and resolution, are available

Applicability

• System compatibility to nearly all deposition chambers and customer specified instrumentation

• Best applicability to IAD and sputter deposition processes