LASER - World of PHOTONICS 2023: Plant and System Technologies

Coaxial multi-diode processing head (DiCoLas)

• Up to 6 fiber-coupled laser diodes applicable

• Collimation and focusation for each single laser beam

• Individual beams converge at the focal point

• Concept allows the adjustment of the stick-out to the focus position

• Compact and lightweight design with a combined weight of 1.5 kg

• Shielding gas coverage provided within the nozzle holder

• Possibility to provide two wire materials simultaneously to the processing zone

• Investigation of in-situ alloying and fabrication of functionally graded materials

• Examination of the mixing behavior

• Directional independence for individual seams is maintained

Motivation

• Material-efficient production of alloys in-situ

• In-situ production of functionally graded materials

Function / Properties / Characteristics

• Individually controllable wire feeding velocity

• Adjustment of the material mixing ratio on the fly

• Homogenous mixing of alloying elements

Applications

• Claddings with graded material transitions

• Additive manufacturing with local changes in part properties

Parameters

• Wavelength: 970 nm, 445 nm

• Output power: 630 W

• Type of laser: diode laser; fiber laser

Processed material

• Martensitic hardening steels

• Metal wires

Please find more information about our process and system technology here.

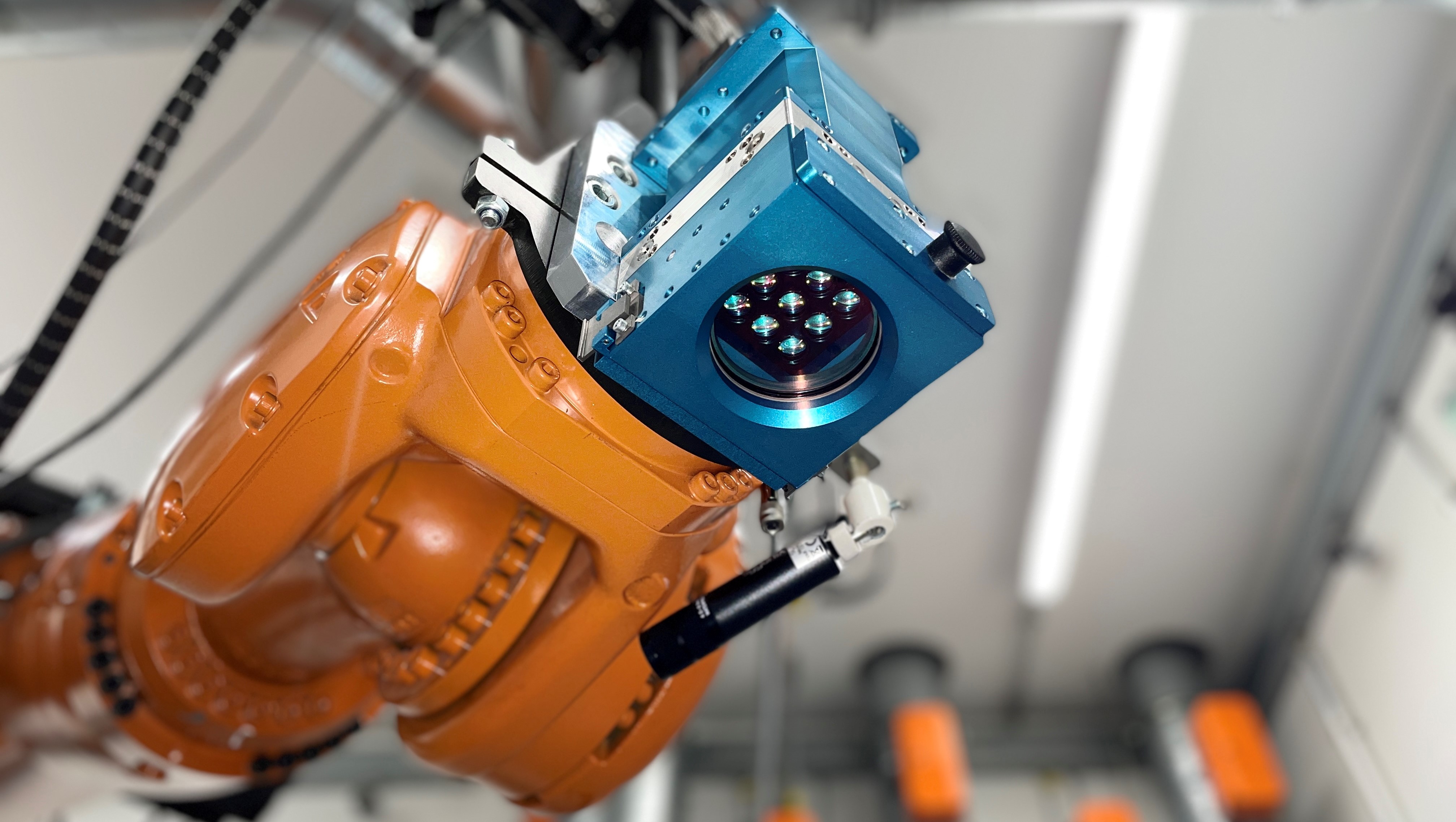

MULTISPOT head with individually controllable laser spots

Motivation

The aim of the MultiSpot project was to develop a welding head based on individual modularly controllable laser spots to be able to adapt the desired intensity distribution within a laser focus to meet the demands of each weld seam geometry.

Function / Properties / Characteristics

Nine individual controllable spots make it possible to partially adapt the laser power to both the weld seam geometry and the material properties.

Applications

• Laser transmission welding of unreinforced and reinforced thermoplastics

• Heat conduction welding of carbon fiber-reinforced thermoplastics

• Laser joining of thermoplastics to metals

Laser source

• Diode laser

• Wavelength 980 nm

• Max. Power up to 1 kW

• 9 individual controllable laser spots

Processed material

• Thermoplastics such as PA6, PE, PP, PPS, PEI

• Carbon fiber-reinforced thermoplastics

• Joining of metal-thermoplastic hybrid parts

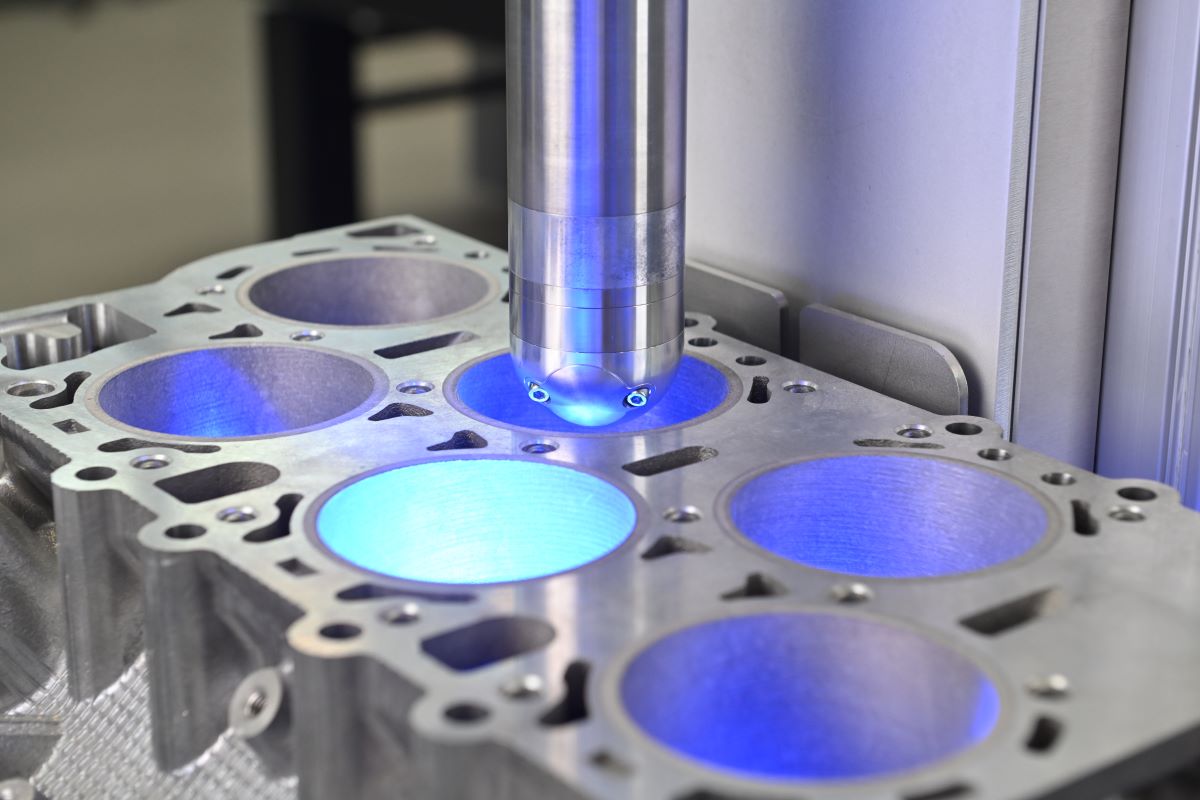

Internal processing laser head (IBK)

Motivation

• Structuring of inner surfaces of cylinders for better adhesion of coatings

• Clean, reliable, and efficient process for coating preparation

Function / Properties / Characteristics

• Laser beam source: single-mode laser, 1080 nm

• Laser power: ~1000 W

• Rotational speed of deflection mirror: max. 9000 rpm

• Pyrometer for monitoring the condition of the deflection mirror

Applications

Preparation of the surface of the cylinder bores of aluminum engine blocks for the application of a high-strength coating